On more than 30.000 sqm.

Said - Stamped

Things are running smoothly at PUEHL

Experience our production and our full capabilities as we successfully combine know-how, team strength and modern production facilities. Quality, flexibility and international service from planning to series production. PUEHL makes it possible.

Quality on all levels

Our production lines are perfectly organized and optimized. Every step is precisely planned to ensure maximum efficiency and quality. Particularly two factors are in focus:

Innovation

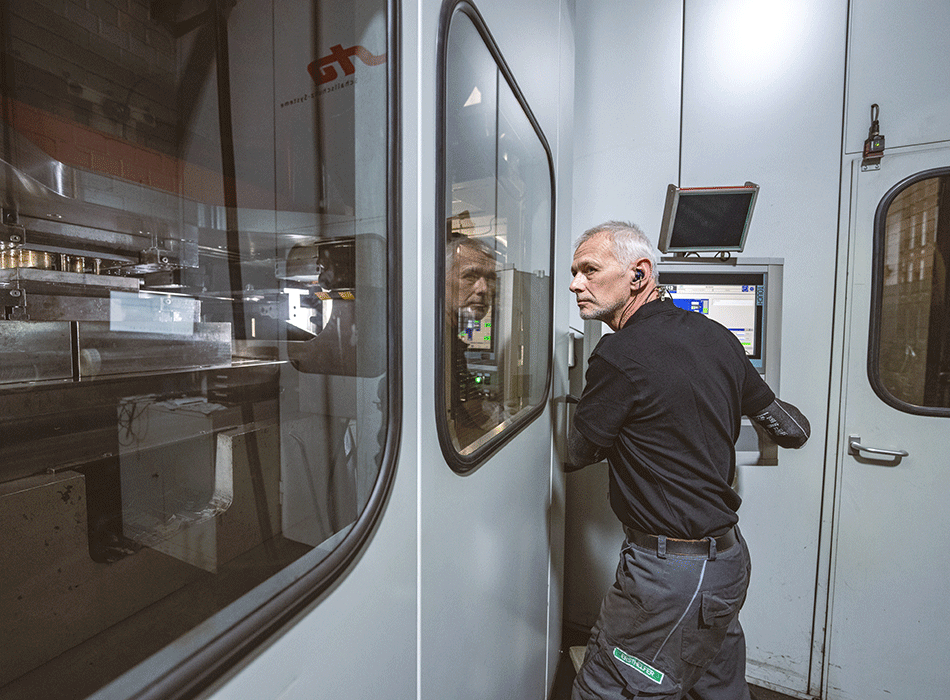

One reason for our success is our consistent investment in the most modern technologies. We rely on automated processes and advanced machinery to increase quality and speed up production in the long term.

Interdepartmental cooperation

Our strong team of highly skilled professionals is responsible for monitoring and operating the machines. Its skills and experience guarantee that production always runs smoothly and product quality remains consistently high.

PUEHL in facts and figures

State-of-the-art high-performance automatic stamping presses with press forces from 100 t to 1,000 t and integrated process monitoring produce standard parts, special parts and drawing parts for various industries. On a total area of more than 30,000 sqm, more than 10 million manufactured parts leave our in-house logistics center every day. We achieve this strong performance with our innovative and automated machinery, continuous optimization of our processes and the profound know-how of our employees.

- Automatic punching presses for material thicknesses of h = 0.5-12 mm and maximum outer diameter of 400 mm

- 22 presses: 1,000-5,000 kN eccentric presses & 3,200-10,000 kN hydraulic presses

- 6 automatic hole punching/embossing machines

- Use of various hot-rolled and cold-rolled steels

- Products made of

- steel

- carbon steels

- case-hardening steels

- ISO 9001 / ISO 14001 / ISO 50001

Your contact to PUEHL

You would like to learn more about PUEHL and our products? We are at your disposal at any time and will be happy to help you.

Sales

Sebastian PieperInquiry form

Simply send us a message via the contact form. If necessary, we will forward your request directly to the relevant department and get back to you as soon as possible.